Additional Features:

- 300 KHz to 6 GHz

- 7-mm

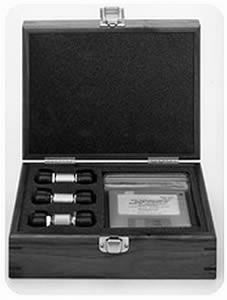

The 85029B 7-mm verification kit has been designed to check the performance of:

- 8753, or 8720D and its test sets

The Agilent 85029B verification kit contains a set of precision 7 mm devices, with data traceable to NIST, used to verify the calibrated performance of an Agilent 8753 measurement system. Measuring known devices, other than the calibration standards, is a convenient way of verifying that the Agilent 8753 measurement system is operating properly. The devices have precision 7 mm connectors and include a 20 dB pad, a 50 dB pad, and a mismatch attenuator. The verification process requires only an Agilent 85031B calibration kit, and an Agilent 85029B verification kit.

The 85029B allows the user to periodically record measured data. This history data is useful for statistical quality control of instrument performance. Also, unusual deviations from historical data can warn the operator of possible degradation in instrument or verification kit performance.

Measuring the devices of this kit and comparing the results with supplied data provides a tops-down verification of an Agilent 8753A/B network analyzer with a 7-mm 50 ohm test-set. The frequency range covered by the Agilent 85029B verification kit is 300 kHz to 6 GHz. The system must be calibrated before performing a system verification.

A tops-down verification is a procedure in which the devices in a verification kit are measured on the 8753A/B system. These measured values are then compared with the NBS traceable data that Agilent supplies with each verification kit. The 85029B verification kit contains three verification devices for this purpose. The kit contains a 7-mm 20 dB attenuator, a 7-mm 50 dB attenuator, and a 7 mm mismatch attenuator. NIST traceable magnitude and phase data is provided with the 85029B verification kit at specific frequencies from 300 kHz to 6 GHz for all four S-parameters.

The uncertainty limits provided with these verification devices are the worst-case sum of the measurement uncertainties of the factory 85029B production test system, plus the measurement uncertainties of the system being verified. If the measured data for the verification devices falls within the supplied uncertainty limits, then the measurement system passes its performance verification.

Residual errors of the measurement system are, in part, due to the characteristics of the calibration devices used during system calibration. You should use the same calibration kit that will be used when calibrating the system for actual measurements. Using a different calibration kit can cause inconsistent performance.

As an example, a user calibrates the system with a calibration kit that is in excellent condition and the system passes the verification procedure easily. The system is then sent to production and is calibrated using a worn or damaged calibration kit. In this case, the residual errors of the system could fall outside the allowable uncertainty limits.

Each 85029B verification kit is measured at the factory in a tightly controlled environment using an 8753 network analyzer. The test system is calibrated with special NIST-traceable standards, allowing the accuracy of the test system to exceed that of a standard 8753. This system is verified daily, using a bottoms-up procedure that quantifies individual sources of measurement error.

| Manufacturer | Agilent, HP, Keysight |

|---|---|

| Condition | Used |